| MODEL | Unit | MICRO4025 | MINI5030 | MAXI6040 | MAX+7540 |

|---|---|---|---|---|---|

| Work tank | mm | 600*400*275 | 700*450*350 | 900*600*400 | 1100*700*500 |

| Work table size (X*Y) | mm | 400*250 | 500*300 | 600*400 | 750*400 |

| Work table travel X | mm | 250 | 300 | 400 | 500 |

| Work table travel Y | mm | 150 | 200 | 250 | 300 |

| Ram servo travel(Z-axis) | mm | 200 | 250 | 300 | 250 |

| Max. distance from electrode plate to table | mm | 450 | 550 | 650 | 750 |

| Work head travel(W-axis) | mm | 250 | |||

| Max. work piece height | mm | 300 | 400 | 500 | 600 |

| Max. electrode weight | Kgs | 40 | 50 | 75 | 100 |

| Max. work piece weight | Kgs | 250 | 400 | 600 | 800 |

| Cross weight | Kgs | 1150 | 1450 | 1650 | 1850 |

| External dimension (W*D*H) | mm | 1200*1000*1800 | 1400*1200*2000 | 1700*1500*2300 | 2000*1800*2600 |

| Oil tank capacity | Liter | 210 | 310 | 460 | 420 |

| Net weight | Kgs | Built-in | Built-in | Built-in | 150 |

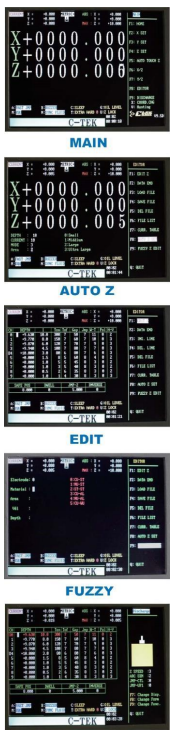

| Model | 30A | 50A | 75A | IOOA | |||||

|---|---|---|---|---|---|---|---|---|---|

| Control Methed and Axis | Close(Z-axis) | Close(XYZ-axis) | |||||||

| Min.Setting Unit | O.005mm(O.001mm) | ||||||||

| Max.Setting Unit | 999.995mm(999.999mm) | ||||||||

| Coordinate System | INC* ABS | ||||||||

| Inching | 0.005mm(0.001mm)unit x1,x5,x10 | ||||||||

| Max. machining current | 30 | 50 | 75 | 100 | 30 | 50 | 75 | Max. machining current |

|

| Total power input | KVA | 4 | 6 | 8 | 12 | 4 | 6 | 8 | Total power input |

| Max.Material Removal Rate | in | 220 | 360 | 540 | 720 | 220 | 360 | 540 | Max.Material Removal Rate |

| Electrode Wear Rate | |||||||||

| Best Surface Roughness | Ra | 0.2 | 0.23 | 0.25 | 0.18 | 0.2 | 0.23 | ||

| External Dimension Packing Dimension | mm | ||||||||

| NET Weight | Kgs | 265 | 270 | 275 | 350 | 265 | 270 | 275 | NET Weight |

| Machining Setting amount Per set | 1 | 30 | |||||||

| Steps | 10 | 10 | |||||||

| Machining Model | Up sparking • Down sparking | XY model(Z-Lock)• XYZ mo | |||||||

| Orbit Cut-ing | No | X, Square, round, hexagon,side spark | |||||||

| Continuous machining Max.hole amount | 1 | 100 | |||||||

Automotive

Aerospace

Medical

Electronics

Home Appliances

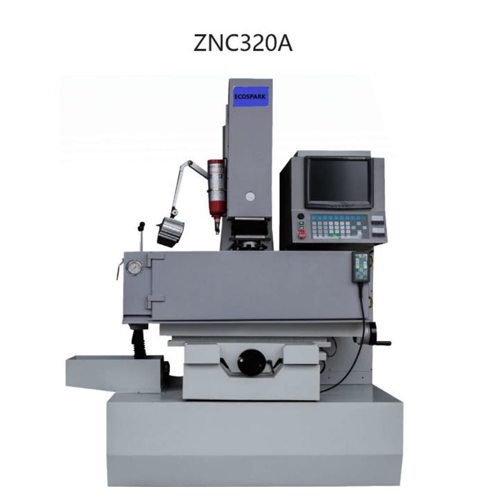

EcoSpark Machine Tools Private Limited specializes in all aspects of Die Sinking EDM, Wire EDM, EDM Drill, and CNC Engraving. We provide comprehensive sales and services for EDM machines, including refurbished options.